MIT Researchers Demonstrate Ship Hull Modifications to Cut Fuel Use by Up to 7.5%

Paper presented at the Society of Naval Architects and Marine Engineers (SNAME) 2025 Maritime Convention shows wedge-shaped vortex generators reduce drag in ship hulls, advancing decarbonization for the shipping industry.

Researchers at MIT have demonstrated that wedge-shaped vortex generators attached to a ship’s hull can reduce drag by up to 7.5%, which reduces overall ship emissions and fuel expenses. The paper, “Net Drag Reduction in High Block Coefficient Ships and Vehicles Using Vortex Generators,” was presented at the Society of Naval Architects and Marine Engineers (SNAME) 2025 Maritime Convention in Norfolk, Virginia October 29-31.

The work offers a promising path toward decarbonization, addressing the pressing need to meet the International Maritime Organization (IMO) goal to reduce carbon intensity of international shipping by at least 40% by 2030 compared to 2008 levels. Achieving such ambitious emission reduction will require a coordinated approach, employing multiple methods from re-designing ship hulls, propellers, and engines, to using novel fuels and operational methods.

The researchers – José del Águila Ferrandis, Jack Kimmeth and Michael Triantafyllou (MIT Sea Grant and the Department of Mechanical Engineering), along with Alfonso Parra Rubio and Neil Gershenfeld (Center for Bits and Atoms) – determined the optimized vortex generator shape and size using a combination of Computational Fluid Dynamics (CFD) and experimental methods guided by AI optimization methods.

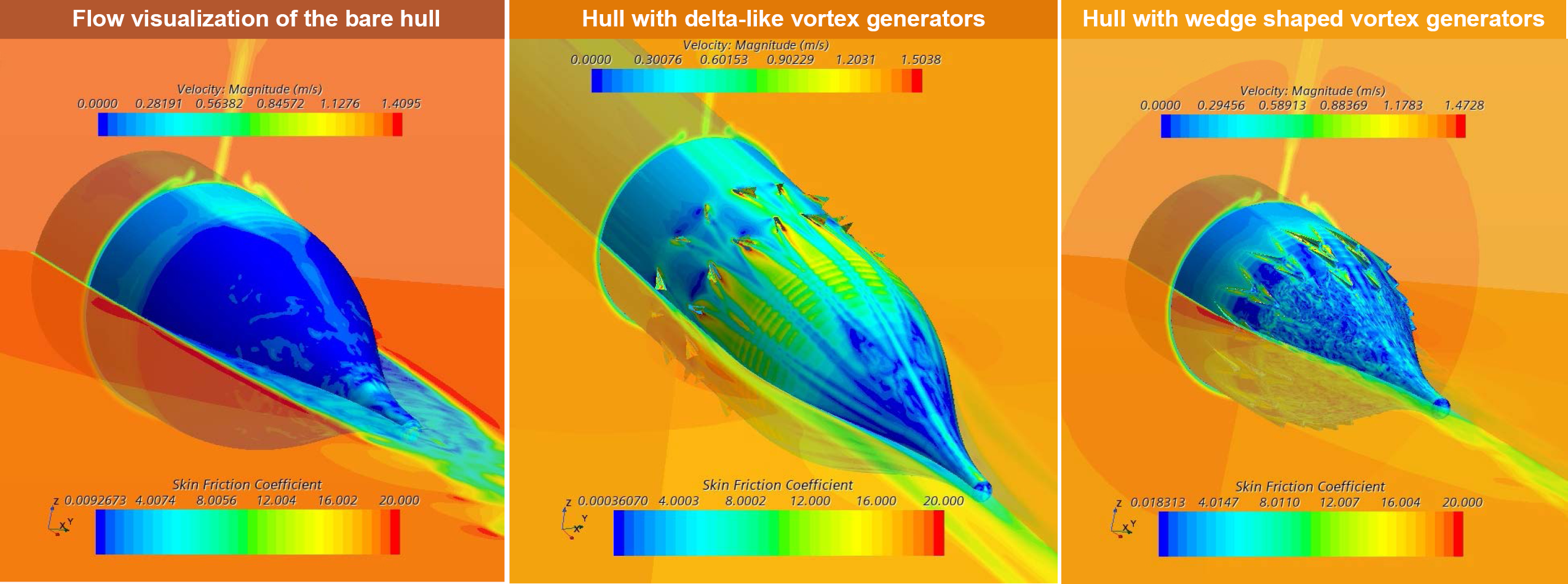

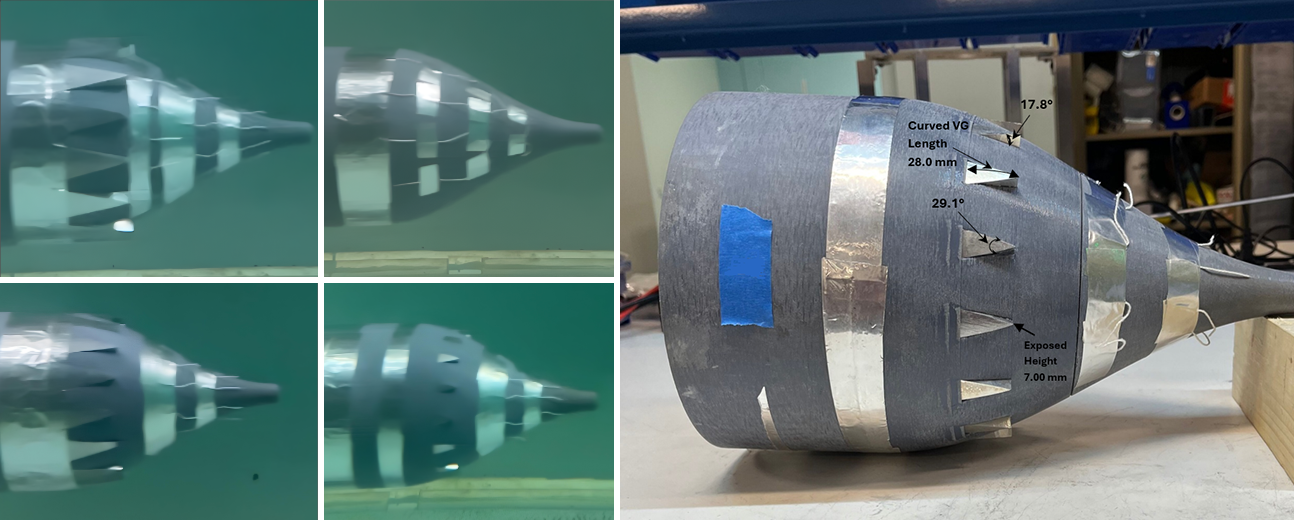

The team first established parametric trends through extensive CFD analysis, and then tested multiple hulls through rapid prototyping to validate the results experimentally. Scale models of an axisymmetric hull with a bare tail, a tail with delta wing vortex generators, and a tail with wedge vortex generators were produced and tested. The team identified wedge-like vortex generators as the key shape that could achieve this level of drag reduction.

Pictured Left: Initial experimental setup, showing the submerged axisymmetric model attached to the towing carriage through a streamlined strut. Right: Experimental Flow Visualization using dye, compared to Computational Fluid Dynamics flow visualization at a speed of 1.3 m/s.

Through flow visualization, the researchers could see that drag was reduced by delaying turbulent flow separation, helping water flow more smoothly along the ship’s hull, shrinking the wake behind the vessel. This also allows the propeller and rudder to work more efficiently in a uniform flow.

“We document for the first time experimentally a reduction in fuel required by ships using vortex generators, relatively small structures in the shape of a wedge attached at a specific point of the ship’s hull.”

– Michael Triantafyllou (Professor of Mechanical Engineering and Director of MIT Sea Grant)

Pictured Left: Tell Tail Comparison: Three iterations of the tail with the bare tail (top right) showing turbulent flow, and uniform reattached flow in the other tails. Right: Tail 3, the best performing configuration in terms of drag reduction.

The findings offer a practical, cost-effective solution that could be implemented efficiently across existing fleets. This study was supported through the CBA Consortium, working with Oldendorff Carriers, which operates about 700 bulk carriers around the world. Extension of this research is supported by the MIT Maritime Consortium, led by Professors Themis Sapsis and Fotini Christia. The Maritime Consortium was formed in 2025 to address critical gaps in the modernization of the commercial fleet through interdisciplinary research and collaboration across academia, industry, and regulatory agencies.

Paper Authors

Dr. José del Águila Ferrandis completed his Ph.D. at MIT in 2024, where he specialized in the application of Scientific Machine Learning to practical engineering challenges within fluid dynamics and structural analysis. His research studies how to encapsulate physics with machine learning to predict complex fluid dynamics, significantly impacting ocean and aerospace engineering. José is a Machine Learning Scientist at the NATO Center for Marine Research and Experimentation (CMRE) and will be taking a faculty position at the Kevin T. Crofton Department of Aerospace and Ocean Engineering at Virginia Tech in 2025.

Jack Kimmeth is a graduate Student in the Mechanical Engineering Department at MIT. He is currently a research assistant at Sea Grant and also an active-duty Officer in the United States Coast Guard. He attended the United States Coast Guard Academy and graduated with a Bachelor of Science degree in Naval Architecture and Marine Engineering with High Honors. After graduation he served onboard USCGC STRATTON (WMSL-752) for two years as an engineering officer and maintained hull, mechanical, and electrical material readiness and trained all personnel on emergency response procedures and directed all emergency responses.

Alfonso Parra Rubio is a PhD student at the MIT Center for Bits and Atoms. He researches structural origami and manufacturing methods for producing morphing structures, metamaterials and cellular structures using primarily metals. His passion for mechanical design spans from initial concept through simulation to physical construction. His work has focused on folding techniques, including their application as aerospace core materials and in non-planar folded antennas for Airbus. At MIT, he has also exploited his role as a maker, creating large-scale metallic and wooden folded pieces, as well as glass blowing. You can follow his projects at www.aprubio.com.

Prof. Neil Gershenfeld is the Director of MIT’s Center for Bits and Atoms, breaking down boundaries between the digital and physical worlds, from pioneering quantum computing to digital fabrication to the Internet of Things. Elected Member of the National Academy of Engineering, Fellow of the American Association for the Advancement of Science and of the American Physical Society. He has been called the intellectual father of the maker movement, founder of a global network of over 2500 fab labs in 150 countries, chairs the Fab Foundation, and leads the Fab Academy.

Prof. Michael Triantafyllou is the Doherty Professor in Ocean Science & Engineering at MIT and the Director of the MIT Sea Grant Program. He teaches and has published over 400 articles in the areas of biomimetic robotics and sensing, dynamics and control of marine vehicles, and experimental fluid mechanics. He pioneered the development of science-driven biomimetic robots. He was Associate Department Head in the Department of Mechanical Engineering, and Director of the Center for Ocean Engineering at MIT. He serves on ABS’s Marine Technical Committee. Life Fellow of SNAME and Life Fellow of the American Physical Society.